SET Innovation Division

SET’s Innovation Division applies operational insight and modern engineering to create advanced traction systems for rail — supporting improved efficiency, greener operation, and greater reliability.

Innovating Traction and Guided Steering

At SET Limited, innovation is not a side activity — it is a natural evolution of how we solve problems. Our Innovation Division grew directly from decades of hands-on experience tackling complex legacy electronics and electromechanical systems that others could no longer support.

What began as expert fault analysis, redesign, and life-extension of obsolete systems became something more powerful: a capability to re-think, re-design, and re-build critical technologies from the ground up. This mindset now defines our Innovation Division.

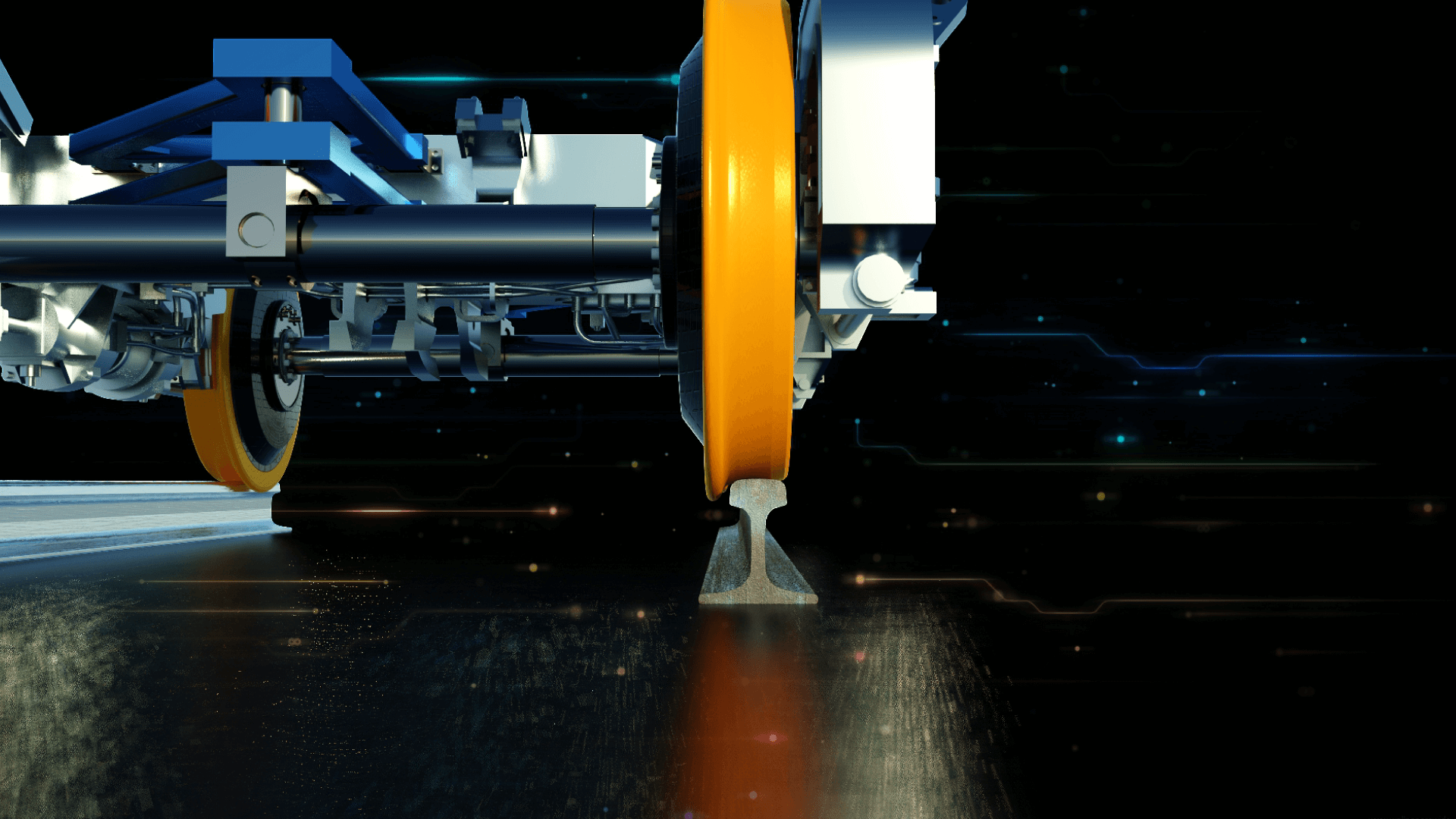

ActiWheel GS is a step-change in rail vehicle traction and guidance — replacing a 200-year-old mechanical paradigm with intelligent, digitally guided wheel control.

Traditional rail vehicles rely on fixed axles and centrally driven traction systems that force wheels to fight the track, particularly on curves. The result is excessive wear, high energy consumption, noise, and ongoing safety and maintenance challenges.

ActiWheel GS re-imagines this relationship entirely.

The Technology

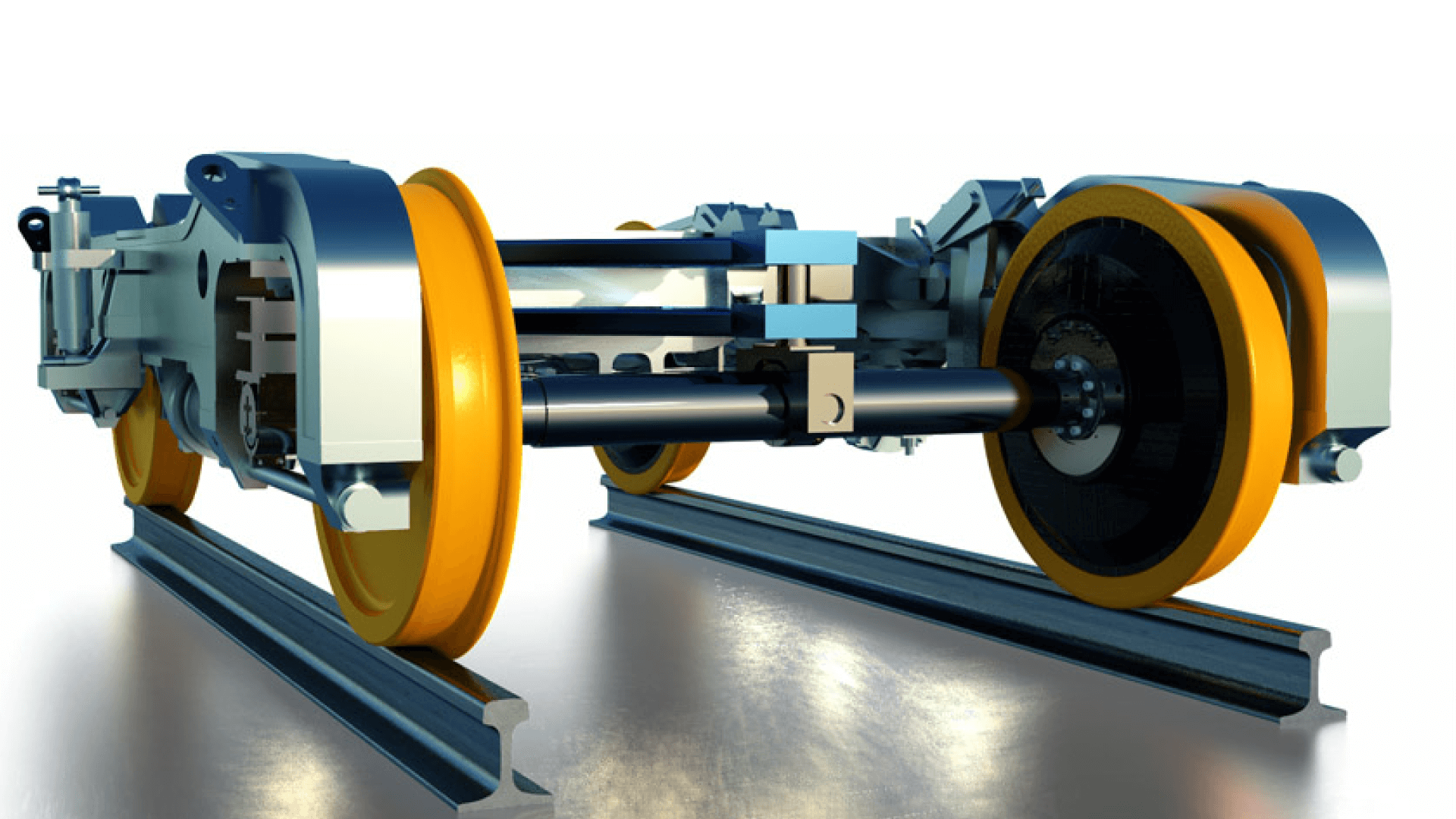

Independently Motored, Digitally Guided Wheels

At the core of ActiWheel GS is a fundamental shift in traction delivery:

Each wheel is independently driven by its own electric motor

Electronic guidance algorithms continuously monitor wheel position

Torque is precisely controlled to actively steer the wheelset back to centre

Instead of passive alignment imposed by rigid axles, ActiWheel GS actively maintains optimal wheel–rail contact in real time.

This enables the vehicle to:

Negotiate curves with the rolling resistance of straight track

Eliminate rolling contact fatigue (RCF) and gauge corner damage

Maintain consistent adhesion across varying track and weather conditions

The system replaces gearboxes, cardan shafts, fixed axles, and traditional braking systems with a simpler, digitally controlled architecture — reducing mechanical complexity while increasing performance.

Innovation motion

In 1999 the Wheel Motor idea came into being as one of SET’s directors was enjoying his miniature railway in the garden.

His concept was to locate the motor within the wheel and by controlling the delivery of power enable the control of torque to each individual wheel.

This, in theory, would make it possible to manage the issue of slip and improve traction. Following a successful patent application, the idea ended up going on hold due to other business commitments until 2006.

In 2008, following the employment of a dynamometer rig at Nottingham University where the prototype motor was tested to 75kW, the Wheel Motor was fitted to Blackpool tram number 636 and, with the support of Blackpool Transport, completed over 2000km on Blackpool seafront.

In 2012 the RSSB put out two calls to meet the industry’s rail technical strategy: Future Railway.

1. Infrastructure

Generic designs are used for cost-efficient, holistic infrastructure layouts.

Train suspension characteristics are included in track designs to minimise damage on train/infrastructure interfaces and optimise system-level costs.

Research into vibration, noise reduction and low carbon construction processes should be carried out to minimise the impacts of new and current lines on the surroundings and the environment.

New designs of switches and crossings reduce failures to negligible levels and reduce the costs and disruptions associated with maintenance interventions.

2. Rolling Stock

The overall efficiency and effectiveness of rolling stock will be delivered increasingly through progressive improvements in sub-systems, including:

Mechatronic bogies

Adaptive braking systems

Improved passenger compartments

Integrated diagnostic systems

Innovative bogies designs could minimise track impact and wear while extending the operating range of trains and reducing track access charges and energy use.

Matching braking forces with adhesion and speed while maximising energy recovery may be achieved through using a combination of braking systems such as pneumatic, magnetic and eddy current.

Simplicity

Many of the strategies in the themes offer concepts supporting a simple railway. A whole-system approach for rolling stock and infrastructure should reduce asset failures and maintenance requirements.

The text in blue italics highlights areas where the Wheel Motor / Acti-Wheel would make a significant if not disruptive intervention.

In 2016 SET successfully presented the concept to the RSSB and was awarded with a grant to further develop the project.

Following the successful acquisition of the grant in 2016 ‘Acti Wheel’ was actually Stage 2 of the overall wheel motor project and was to feature lateral position sensing and steering algorithms for heavy rail using low PYS bogies. One of the biggest issues facing the rail infrastructure is Rolling Contact Fatigue. This occurs due to the contact between the wheel and the rail. Conditions under the contact patch are always severe and the yield stress of the rail steel is always exceeded, on at least a microscale, due to the surface roughness of the wheel and the rail.

Actively positioning the wheels and therefore the contact patch at the optimum point of the rail, along with active torque control, will practically eliminate RCF. This is because ideal (close to radial) steering reduces the energy in the contact patch to a point where RCF does not occur and wear is very small.

The following media clip provides further information and shows our demonstration train in motion using a successfully implemented control system actively positioning its wheels during its journey:

Benefits across the rail environment

Track Owners & Infrastructure Managers

Elimination of rolling contact fatigue (RCF)

Reduced rail head and gauge corner damage

Significant reductions in maintenance, repair, and renewal costs

Improved track reliability and availability

Digital feedback on track condition and adhesion

Reduced need for personnel working on-track

Rolling Stock Owners & Operators

Major reductions in wheelset maintenance and replacement

Improved vehicle reliability through simpler traction architecture

Lower energy consumption, particularly on curved routes

Reduced operating and whole-life costs

Extended asset life for both vehicles and infrastructure

Compatibility with existing and future power sources

Reduced track access charges driven by lower infrastructure wear

Government & Transport Authorities

Reduced carbon emissions through improved energy efficiency

Elimination of brake dust and particulate pollution

Lower noise levels in urban and suburban environments

Improved network resilience and service reliability

Alignment with decarbonisation, air quality, and accessibility objectives

Passengers

Smoother, quieter rides

Improved service reliability

Cleaner air quality in enclosed and underground stations

A more comfortable and accessible rail experience

Why it matters

Conventional wheelset technology not only accelerates wear and energy loss, it constrains operational performance — particularly under poor adhesion conditions, where speed restrictions reduce network capacity and reliability.

ActiWheel GS directly addresses these systemic issues, delivering:

Lower maintenance costs

Reduced energy consumption

Improved safety margins

Lower carbon footprint

Enhanced passenger experience

It represents not an incremental improvement, but a new architecture for rail traction — one designed for modern performance, digital integration, and sustainable transport systems.

redefining how rail vehicles interact with the track.

redefining how rail vehicles interact with the track.

Case studies

GET IN TOUCH

Let’s start a project together

+44 (0) 1332 346 035

info@set-gb.com