In 1999 the Wheel Motor idea came into being as one of SET’s directors was enjoying his miniature railway in the garden.

Implementation

It's not about ideas. It's about making ideas happen.

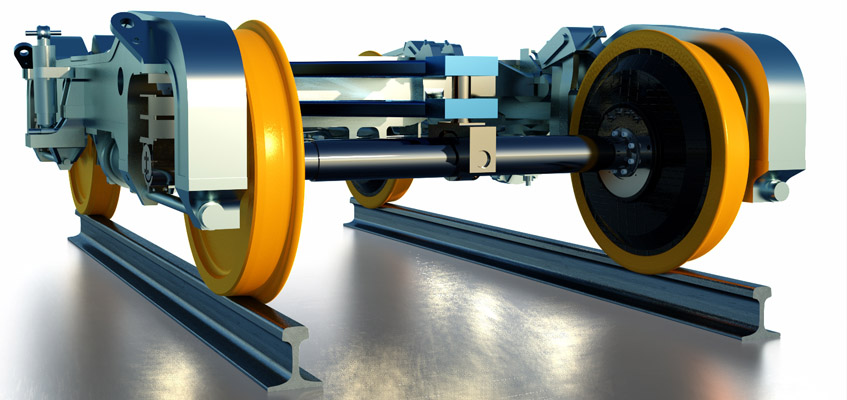

His concept was to locate the motor within the wheel and by controlling the delivery of power enable the control of torque to each individual wheel.

This, in theory, would make it possible to manage the issue of slip and improve traction.

Following a successful patent application, the idea ended up going on hold due to other business commitments until 2006.

In 2008, following the employment of a dynamometer rig at Nottingham University where the prototype motor was tested to 75kW, the Wheel Motor was fitted to Blackpool tram number 636 and, with the support of Blackpool Transport, completed over 2000km on Blackpool seafront.

In 2012 the RSSB put out two calls to meet the industry’s rail technical strategy: Future Railway.

1. Infrastructure

- Generic designs are used for cost-efficient, holistic infrastructure layouts.

- Train suspension characteristics are included in track designs to minimise damage on train/infrastructure interfaces and optimise system-level costs.

- Research into vibration, noise reduction and low carbon construction processes should be carried out to minimise the impacts of new and current lines on the surroundings and the environment.

- New designs of switches and crossings reduce failures to negligible levels and reduce the costs and disruptions associated with maintenance interventions.

2. Rolling Stock

The overall efficiency and effectiveness of rolling stock will be delivered increasingly through progressive improvements in sub-systems, including:

- Mechatronic bogies

- Adaptive braking systems

- Improved passenger compartments

- Integrated diagnostic systems

- Innovative bogies designs could minimise track impact and wear while extending the operating range of trains and reducing track access charges and energy use.

- Matching braking forces with adhesion and speed while maximising energy recovery may be achieved through using a combination of braking systems such as pneumatic, magnetic and eddy current.

Simplicity

Many of the strategies in the themes offer concepts supporting a simple railway.

A whole-system approach for rolling stock and infrastructure should reduce asset failures and maintenance requirements.

The text in blue italics highlights areas where the Wheel Motor / Acti-Wheel would make a significant if not disruptive intervention.

In 2016 SET successfully presented the concept to the RSSB and was awarded with a grant to further develop the project.

Why we stay ahead

Our successful approach to problem solving is derived from creative thinking, a high level of engineering expertise, a scientific approach, and practical, hands-on experience.

Our successful approach to problem solving is derived from creative thinking, a high level of engineering expertise, a scientific approach, and practical, hands-on experience.