Actions taken prevented reoccurrence of the symptoms on overhauled units

The Problem

Failure rate of traction motor monitoring panel was increasing, causing service disruption

Investigation

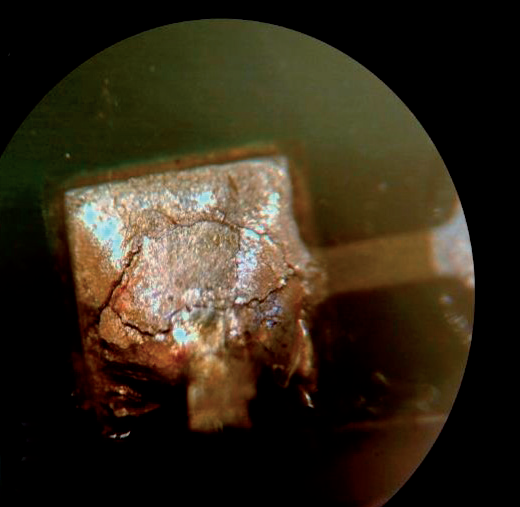

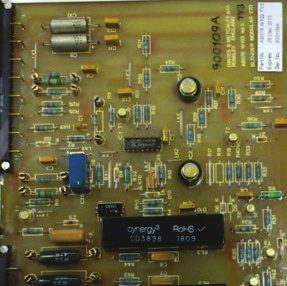

- Fault was traced to cracking of internal PCB in a voltage monitoring device (VMD) fi tted to the monitoring panel main PCB.

- SET conducted vibration testing of the panel to verify hypothesis that resonance of the panel was capable of causing the observed cracking. Tests indicated that the VMD was seeing vibration levels far in excess of those specifi ed for the device when tested at levels specified in EN61673.

- Tests indicated that a previous modifi cation made by the OEM had reduced low frequency fl exing of the main PCB but had not addressed the higher frequency resonance and had introduced new resonance modes.

Solution

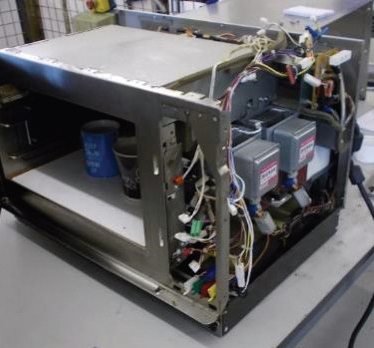

- Sample microwave reverse engineered to produce schematics and to understand the interface and interaction with the programmer PCBs and assemblies created

- Comprehensive modifi cation procedure defi ned to ensure that electrical and microwave safety were not compromised by the modifi cation, as well as ensuring that the desired interrupt rejection was achieved

- One unit was modifi ed and the process was verified

Result

- Report with recommendations on design changes (verified during tests) to bring vibration levels at the VMD within its specified range

- Actions taken prevented reoccurrence of the symptoms on overhauled units